Principles of Hydraulic System Design

- This event has passed.

Principles of Hydraulic System Design

7th January 2019

One event on 13th January 2020 at 12:00 am

One event on 2nd March 2020 at 12:00 am

One event on 4th May 2020 at 12:00 am

One event on 26th December 2019 at 12:00 am

Event Navigation

Member price – £995 + VAT

Non-member price – £1,100 + VAT

Duration – 3 Days

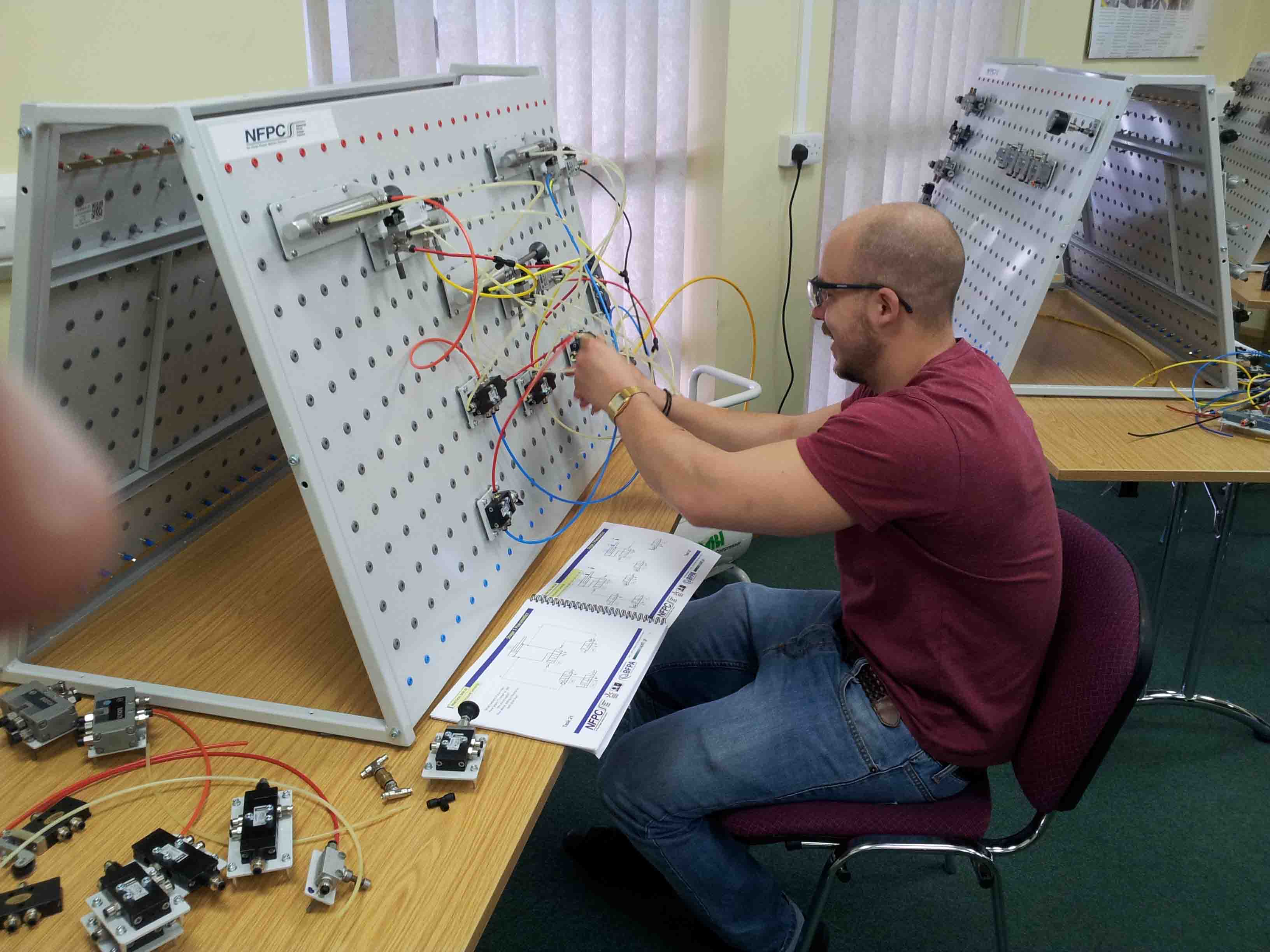

This course is for those involved in the modification, design and planning of hydraulic fluid power systems. The course offers an introduction to the formulae and units used in calculating values for prime movers, pumps, hydraulic motors, cylinders, reservoir sizes and selection methods for combination valves. The course also introduces the candidate to the more common building blocks found in hydraulic systems.

The programme is created to benefit Technical Sales Representatives, Sales Engineers, Applications Engineers, Project Engineers and Design Engineers involved with writing specifications, planning, purchasing, and designing hydraulic systems.

Course Aims

To improve knowledge and overall understanding of hydraulic system and component performance behaviour enabling you to make better, and more confident, decisions relating to modifications, component compatibility and selection, and system troubleshooting.

- This course aims to introduce the candidate to the logical steps needed to design a new hydraulic system, also planning modifications to existing hydraulic systems.

- The candidate will develop methods on how to plan the duty cycle of a machine in order to optimise hydraulic system performance

Course Objectives

On completion of this course, candidates will have knowledge of:

- The methods used to correctly determine the load of a machine.

- The methods used to correctly determine the size the hydraulic actuator (cylinders and hydraulic motors).

- The methods used to correctly select control valves.

- The methods used to correctly size a pump, it’s prime mover and associated reservoir.

- How flow control influences fixed and variable pump circuits, inclusive of system performance.

- How to correctly determine the heating and cooling requirements of a system.

- How to correctly size pipework and hoses.

- How to calculate the flowrate required for turbulent flow flushing.

- How to recognise and implement common circuit tips and techniques to improve machine performance (i.e. unloading, multiple pressure selection, etc.)

- How to correctly place filters for optimum system fluid cleanliness.

- How to plan the duty cycle of a machine.

Programme Objectives, During the sessions of this course candidates will:

- Carry out a Case Study applying basic and hydraulic formulae to correctly size the hydraulic system

- This Course will involve a number of applied calculations, please ensure that you are fully prepared for this and bring with you a calculator

- Use SI and common-place derived units of measurement

- Carry out a simple task to design a hydraulic circuit to achieve a given machine function